|

|||||||

HUGO JUNKERS (1859-1935) A great German engineer of innovation as his many patents in varied areas (gas engines, aeroplanes etc.) show. The name Junkers is mainly known in connection with aircraft, which were produced under his name for the Luftwaffe during World War II . By then however, the Nazi government was running his companies and Hugo Junkers himself was dead. Hugo Junkers was born on February 3rd , 1859 in a small town named Rheydt near Munchengladbach in Germany . He was the third of seven sons of Louise and Heinrich Junkers . Father Heinrich was the owner of a small textile company in Rheydt, which ensured that the family had a good financial backing. In 1867, at the age of ten he attended the Junior High School. Two years later his mother died. Six years later his father re-married a Louise Pfaff, so bringing back a woman into an all male family. Hugo finished school in 1874, and then moved to a school at Barmen in 1875. Three years later at the age of nineteen he finished his education. Over the next five years he studied engineering at the University of Berlin , moving to several other major universities before qualifying as a mechanical engineer in 1883. After a short spell as technical manager at his father's textile company at Rheydt, he returned to Aachen for additional studies in electrical engineering. Parallel to these studies he took other jobs at several Aachen mechanical companies until 1885. Two years later he moved back to Berlin , to continue electrical engineering studies, as well as some economical studies obtaining the title of Building Master . In November 1887 his father Heinrich Junkers died in a gas accident, when ventilation ducts in the gas lines did not close completely and leaking gases poisoned him. The textile company of the Junkers family was then taken over by his eldest brother. Hugo returned to Berlin in 1887 to concentrate in the field of electro-mechanics plus some economical trade lectures at the Research Institute of Prof. Slaby . At this time he was also involved in technological questions regarding gas engines. A year later Wilhelm von Oechelhauser of the German Continental Gasworks in Dessau was looking for a young engineer, who would be able to further the development of the gas engine. Oechelhaeuser asked Prof. Slaby if he knew of an appropriate candidate for that job and Prof. Slaby recommended Hugo Junkers, at the age of twenty-nine. Junkers tried to improve the performance of gas engines, based on an Oechelhauser idea, but after one year the results showed, that these techniques would not be suitable for large-scale gas engines, as Oechelhauser had hoped. Therefore these approaches were abandoned and Junkers left the DCG in late 1889. However, in 1890 Junkers and Oechelhauser founded the Laboratories for gas engines at Dessau . August Wagener had already joined Junkers' in research work at the DCG in November 1889 both were joined by Emil Wergien and Wilhelm Lynen in March 1891. Initially the Laboratories were located in Dessau , but were transferred to the DCG area. Oechelhaeuser himself financed Junkers studies at the laboratories, but no longer influenced them. Together with his three assistants Junkers continued the research for an improved gas engine. But it took until 1892, when the first useful Double-Piston Gas Engine Model VI with a power of 100PS was ready. Junkers and Oechelhaeuser protected their gas engine with a patent on the 8 th July 1892 . This was the first patent out of a larger number of patents, which were assigned to Junkers. Research on a larger 200 PS gas engine Model VII was already under construction, when Junkers and Oechelhaeuser separated on 17 th April 1893 . The team was then split, with Wagener remaining with Oechelhaeuser at DCG. Lynen became private assistant to Prof. Slaby in Berlin , while Emil Wergien remained with Junkers. Oechelhaeuser himself continued his research on a Model VIII, which was a 25PS two stroke Double Piston Engine in 1893. Oechelhaeuser later delivered two further engines Model IX and X to Bamag.

At the age of 39 in 1898 he married 22-year-old Therese Ida Sidone Bennhold at Dessau before moving to Aachen . Their first child was born in January 1899 followed by a further 11 children. Junkers became the head of the Machine Laboratories of the Technical High School , along with the family in Aachen until the early 1920's. In 1902 a private venture of Junkers laboratory was founded and was financed from ICO at Dessau for Oil Engines under Wilhem Scheller. The results from these laboratories were used in Aachen for their commercial products. By 1906 he was so overloaded with his official educational tasks, his company in Dessau and with the death of his brother Max, who had managed the Junkers company at Rheydt since the death of their father; he became ill and had to take time off. The Laboratories were then taken over by Prof. Langer. When he returned some months later in 1907 all private research and experimental units had been combined in the Experimental Laboratories, which mainly focused on the development of large-scale engines, to be used in ships. In November 1910 he decided to improve his research studies for ship engines and asked for a one-year research vacation from the Technical High School . On returning from his research, he decided to retire from his educational and scientific lectures after some fourteen years. Sir William Doxford and Sons

When WW1 broke out in 1914 the cooperation between Junkers and Doxfords came to an end. Doxfords went back to producing steam turbines for destroyers, under the General Manager of Mr I.M. Reed; the steam turbines were built from drawings supplied by John Browns of Clydebank and the admiralty. A total of 21 Destroyers were built, each carrying a 27,000bhp engine. At the same time work continued on the development of the second engine.

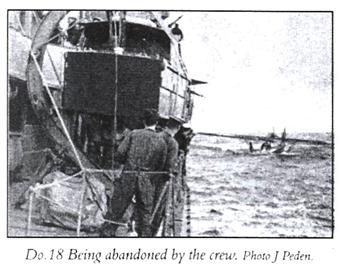

With the ending of W.W.1 in 1918 the cooperation was reinstated. Doxford acquired the license rights for the production of an improved Junkers engine design. In 1921 two 4-cylinder Junkers-Doxford oil engines were installed into the M.S. Yngaren and M.S. Devon City . These engines were large-scale engines of 3000 HP. A further fourteen engines were built and used in Doxford ships until 1926. M.S. Yngaren

William Doxford and Sons Ltd. also sold license contracts for the Junkers-Doxford engine to the Sun Ship Building Company in the U.S.A. The cooperation between Doxford and Junkers therefore became the most successful engagement of all Junkers' oil engines, which was finally terminated in 1926. Doxfords then went on to sell license contracts for the building of its engines to other engine and shipbuilders companies throughout the world. Ships, Equipped with The Doxford-Junkers Engine

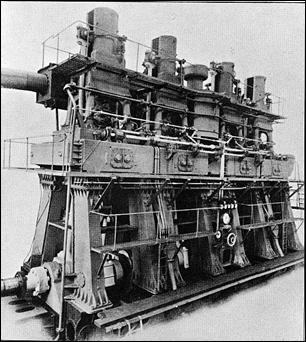

3000 HP. Junkers Schiffimaschine

Built At Wm Doxfords Sunderland 1921 1 Yngaren (built Doxfords June 1921, 9000 to, 3000HP, to Sweden) 8 Silverfir (built Laings Jun 1924, 8225 to, 1760HP, U.K.) Technical Data : THE DOXFORD experimental SUBMARINE ENGINE

1915-1917 THE DOXFORD SUBMARINE ENGINE During the war years of 1915 to 1917 Otto Keller was asked by the British Admiralty if Doxfords could design and build a high-speed single cylinder experimental engine that might replace the existing engine in the ‘K' class type submarine. The engine they came up with developed 400bhp at 360 rev/min with a cylinder bore of 370mm and a stroke of 720mm. The power output per cylinder was considerably in excess of that in use at the time, which was approximately 100bhp/cylinder. The engine drove a four-stage blast air compressor, designed for a working pressure of 1800 lb/sq in, with a scavenge pump having a swept volume which was twice that of the working cylinder and a mean indicated pressure of 180lb/sq in. The differential stroke arrangement was employed for the first time in this engine. The lower piston being 390mm and the upper piston 330mm. The differential stroke arrangement became standard on the Doxford engine in 1926.

The idea behind the production of this high speed single cylinder experimental unit was that four sets of six cylinder engines with each cylinder developing 400bhp could produce a total power of 9600bhp, with each engine arranged in tandem pairs driving twin screws, and they would occupy approximately the same machinery space as the turbines in the present K-class submarines; the same sea speed would be maintained but with about half the fuel consumption and therefore doubling the radius of action. WW1 ended before this interesting development was sufficiently advanced to justify full-scale tests, and therefore the project was abandoned. The Admiralty subsequently acquired this experimental engine, and although this engine was the only new piece of construction undertaken from 1915-1918, which saw the completion of some important technical development, the principal achievement being the realisation of the solid injection fuel system. Also during 1913-14, Junkers Company produced several Oil Engines before it was dissolved on the outbreak of W.W.1. All Junkers activities were then focused on aircraft engines. The Junkers-Fokker-Werke Company was founded in 1917 and produced a total of 321 aircraft. Fokker left Germany after the war as he and Junkers refused to cooperate with each other. The Allies prohibited Germany from building aircraft until 1925. During this period, Junkers sort other markets outside Germany , for his new aircraft designs the USA , Russia , Sweden , and Turkey being among them. He went on to form the Department of Air Traffic as airlines were now flying to all parts of Europe . Always looking for further utilizations for his aircraft he set up departments for crop spraying by aircraft, cargo flights, the establishment of pilot education and the standards for aircraft maintenance. Some aircraft were modified into air ambulances. It was estimated that worldwide Air traffic was performed by around 40% of the Junkers Airline Company. This company was taken over by Luft Hansa in 1926 after the financial crash of 1925. Losses in his other companies both in Germany and abroad led the government to take them over. However after fourteen months due to European pressure they handed back the shares to Junkers.

At Jumo he returned to the idea of the Oil Engines, laying the foundations for the JUMO 205 (less well known is that Hugo Junkers also laid the foundations for future jet and rocket engines.) The JUMO 205 engine was a diesel opposed piston engine developed in 1928. Otto Maden was behind most of the research and design work; while Junkers did not participate much, he did influence the development in the aircraft of the thirties . (Another known fact, that the second aircraft to be shot down in WW2 was a JUMO 205, about 100 miles east of the River Tyne . The engine is now on display at the Sunderland Air Museum .) Once again looking for new areas to get involved with, he contacted Bruno Urban, an architect from Munich . He had had discussions with him in 1927 about several experimental constructions, namely phone boxes, garages, kiosk boxes, and metal doors. While looking into containers, for trains and lorries. This was not the first time he had looked at the architectural business. Back in 1924 he had discussed the possibilities of movable aircraft hangers. Several of this type were made and sold to England Turkey and Iceland by The Junkers Lamella Company. The second financial crash came for Junkers in 1932 when he was unable to repay loans. The G38 and the JUMO 204 developments were the most expensive. Two possible partners for the companies were Fokker and Henschel. Junkers was not prepared to sell his aviation complex, but finally gave up and sold it to Robert Bosch for 2.6 million reich marks. Bosch not only got the facilities but the right to use the name JUNKERS. His third and final crisis came three days after Hitler came to power. The Defence Ministry asked him to transfer all of his patent rights, which he refused. Therefore Lammler, the Dessau court investigator accused him of spying. He was then placed under partial house arrest while he was investigated. With the threat of being sent to prison he then agreed to transfer 51% of more than 170 personal patents to the German government. He was then allowed to move to a small town near Munich . The government were still interested in having total ownership, but he refused any further discussions on the remaining 49%. February 1934 saw him placed under full house arrest and he was not allowed to have visitors or work without police presence. He continued to fight for his freedom, but his health became worse during the year. In September 1934 he wrote to Goering asking for a jury decision regarding the accusation against him. Goering advised Dr. Keppler, Hitler's economical consultant for a solution on how to acquire the remaining 49% of stock. After two meetings with Keppler, Hugo Junkers died on the 3 rd February 1935 his 76 th birthday, while still under house arrest. The Nazi government tried to hide the struggle between its officials. They announced that he had retired to devote more time to do personal research. On hearing of his death Goering said that a State Funeral would be most advisable. At the funeral the Nazi government was represented by Rudolf Hess. After his funeral, Junker's wife was forced into accepting 9,050,000 Reich Marks plus a further 3.5 million Reich's Marks for the patents over the next ten years. The Junkers Company at the time was estimated to be worth 32 million Reich Marks. At the end of WW2 Klaus Junkers his son, continued the fight against the government of the Federal Republic of Germany, but without any success. So the Junkers family had finally lost all influence upon the work of possibly Germany 's greatest engineering inventor.  Hugo Junkers Grave at Waldfriedhof in Munich |

|||||||

The engagement of Junkers in the field of gas engines then stopped until the early 1900s, when he founded the Experimental Laboratories for Oil Engines at Aachen .

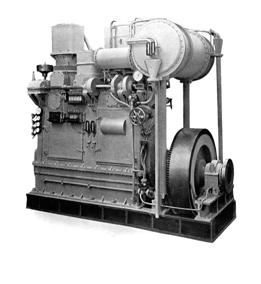

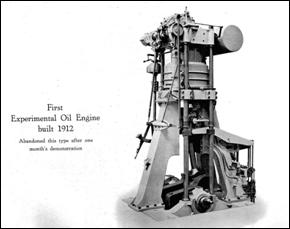

The engagement of Junkers in the field of gas engines then stopped until the early 1900s, when he founded the Experimental Laboratories for Oil Engines at Aachen .  Shortly before WWI the Sunderland based engineering works of Sir William Doxford and Sons started studies for an efficient oil engine for motor driven tramp steamers. In 1912 Doxfords obtained the sole U.K. licence to build the opposed piston design of Oechelhauser and Junkers. Experimention began on a single piston diesel unit, which was abandoned after just one month. Junkers then sent some of his staff to Sunderland to support Doxford's chief engineer Otto Keller and William Purdie during the construction of a second engine. A lot of design inefficiencies were solved prior to the breakout of WW I. In 1913 an opposed piston engine with a bore of 500mm with equal strokes for upper and lower pistons of 750mm, which produced 450BHP at 130rpm. M.I.P. with a 100lbs /m2 was started.

Shortly before WWI the Sunderland based engineering works of Sir William Doxford and Sons started studies for an efficient oil engine for motor driven tramp steamers. In 1912 Doxfords obtained the sole U.K. licence to build the opposed piston design of Oechelhauser and Junkers. Experimention began on a single piston diesel unit, which was abandoned after just one month. Junkers then sent some of his staff to Sunderland to support Doxford's chief engineer Otto Keller and William Purdie during the construction of a second engine. A lot of design inefficiencies were solved prior to the breakout of WW I. In 1913 an opposed piston engine with a bore of 500mm with equal strokes for upper and lower pistons of 750mm, which produced 450BHP at 130rpm. M.I.P. with a 100lbs /m2 was started.